ركائز السيراميك AMB: مادة رئيسية في تكنولوجيا الإلكترونيات المستقبلية

(Active Metal Brazing Ceramic Substrate)

In modern electronic devices, the choice of materials often dictates the performance and reliability of the end products. As technology continues to advance, especially in high-power electronics and high-frequency communication systems, ceramic substrates have become an essential component in electronic products. Among them, السفير (Active Metal Bonded) ceramic substrates have gained popularity due to their exceptional thermal management, electrical properties, and structural stability, making them a go-to solution for high-end electronic devices.

What is an AMB Ceramic Substrate?

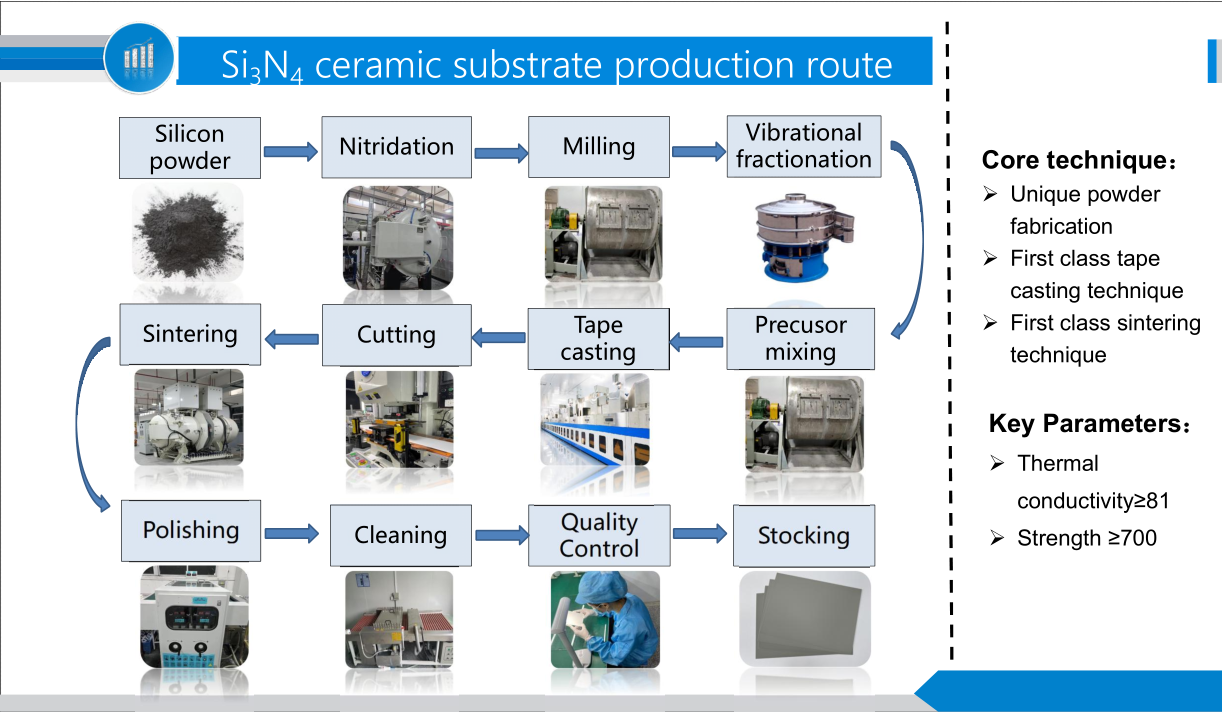

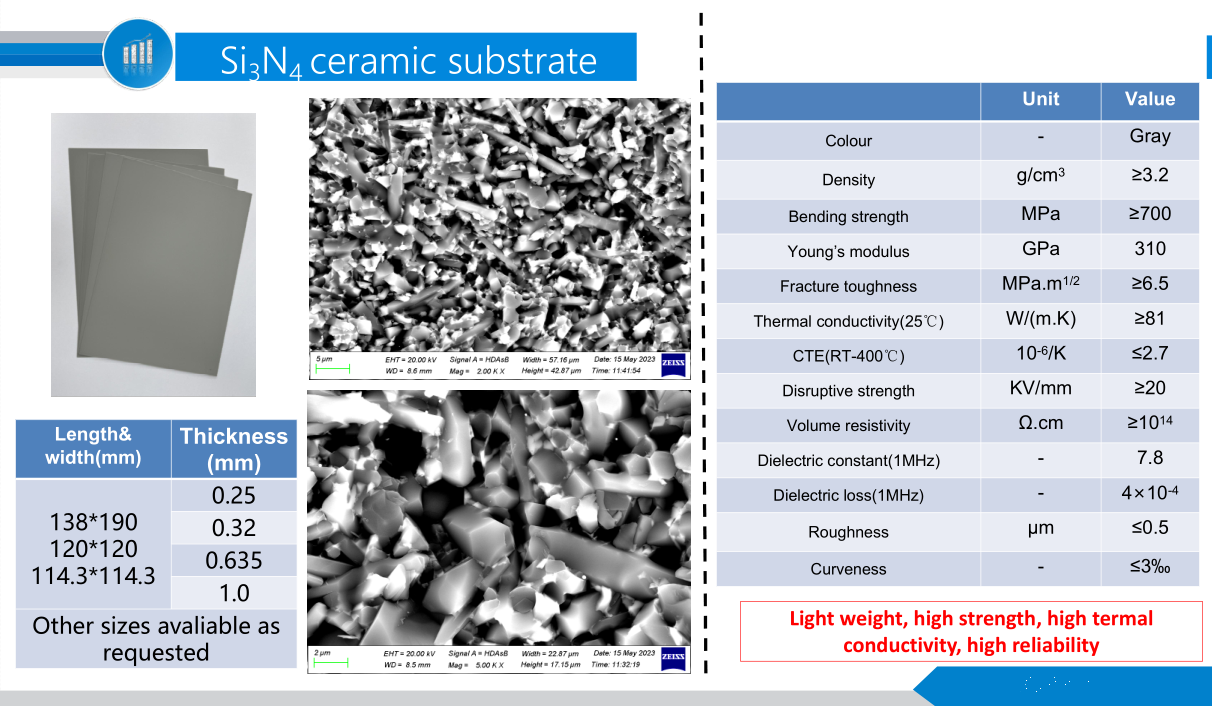

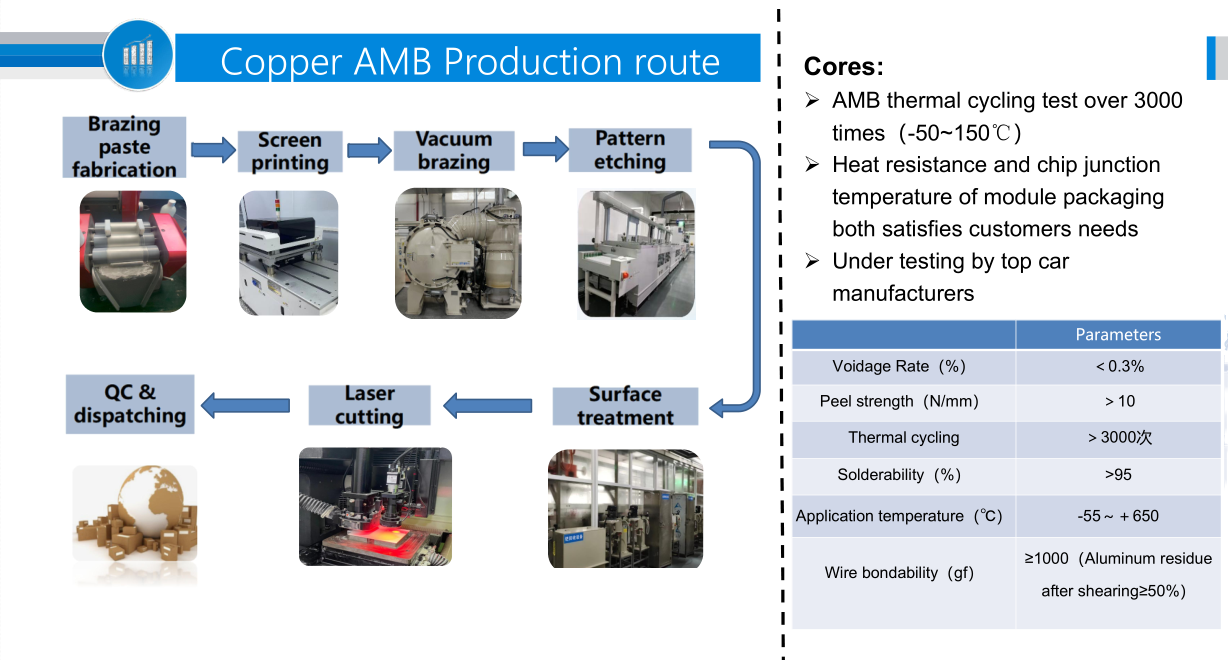

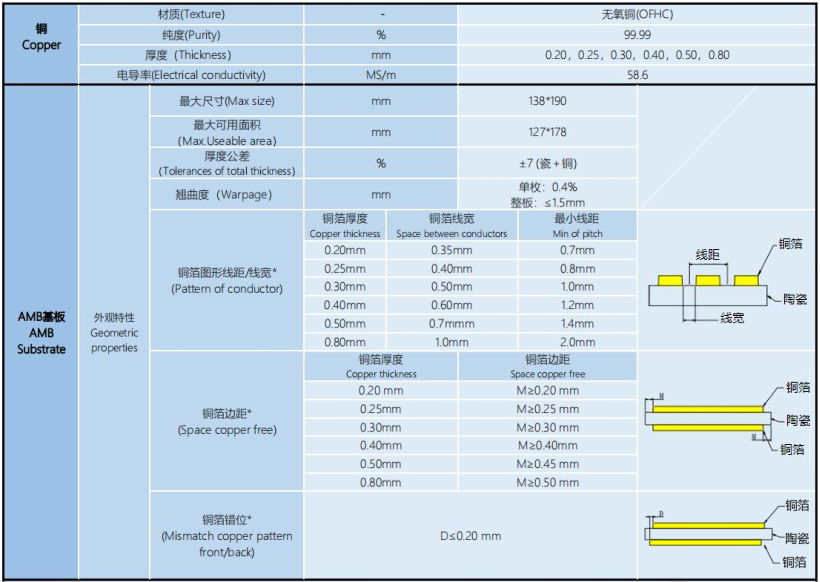

An السفير (Active Metal Bonded) ceramic substrate is a composite material that combines metal and ceramic through a specialized metallization process. Unlike traditional ceramic substrates, AMB substrates not only possess the high thermal stability and excellent electrical insulation properties of ceramics, but also offer enhanced thermal conductivity and greater mechanical strength.

In an AMB ceramic substrate, the metal layer—often made of highly thermally conductive metals like copper or aluminum—is tightly bonded with the ceramic base (such as alumina, نيتريد الألومنيوم, or silicon nitride) through a chemical bonding process, rather than simple physical adhesion. This results in a robust metal-ceramic interface, significantly improving both thermal conductivity and electrical performance.

Key Advantages of AMB Ceramic Substrates

- Excellent Thermal Management

As electronic devices become more powerful, managing heat has become a critical challenge. AMB ceramic substrates significantly enhance heat dissipation thanks to their metal layer, particularly copper, which allows rapid heat transfer away from high-power components. This reduces the risk of damage or performance degradation due to overheating. - Superior Electrical Insulation and Stability

The ceramic materials used in AMB substrates provide excellent electrical insulation, which helps to prevent short circuits and signal interference. الاضافه الي ذلك, ceramics are highly resistant to oxidation and corrosion, ensuring long-term stability even in harsh environments. - High Mechanical Strength and Reliability

Ceramic materials inherently possess high mechanical strength, which ensures that AMB substrates can maintain stability under high temperature, high-frequency, and high-load conditions. The metal-ceramic bonding also strengthens the overall structural integrity, minimizing physical damage and material fatigue over time. - Versatility Across Various Applications

AMB ceramic substrates are widely used in power semiconductors, automotive electronics, LED lighting, communication devices, and power modules. They are particularly suitable for applications requiring efficient heat dissipation and long-term reliability.

- Excellent Thermal Management

Applications of AMB Ceramic Substrates

- Power Electronics

Power semiconductor devices such as IGBTs (Insulated Gate Bipolar Transistors) and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) are widely used in electric vehicles, industrial automation, and renewable energy systems. These devices generate significant amounts of heat due to their high power output. AMB ceramic substrates, with their excellent thermal conductivity, help to keep the devices at a safe operating temperature, preventing overheating and failure. - LED Lighting

LED lighting systems generate substantial heat due to their high power density. AMB ceramic substrates are used extensively in LED modules because of their superior heat transfer properties, which help extend the lifespan of the LEDs by keeping them cool. - Electric Vehicles (EVs)

In electric vehicles, the power electronics modules are subjected to high power and current levels. AMB ceramic substrates are crucial in these systems due to their excellent thermal management and electrical insulation, ensuring the efficiency and longevity of the vehicle’s powertrain. - Radio Frequency (RF) and High-Frequency Communication

AMB ceramic substrates are also used in RF and high-frequency communication circuits. Their good electrical properties help reduce signal loss and interference, which is critical for maintaining the performance of high-speed communication systems.

- Power Electronics

Challenges and Future Outlook of AMB Ceramic Substrates

Despite the advantages, AMB ceramic substrates face some challenges. Their production process is relatively complex, and the manufacturing costs are higher compared to traditional substrates. This remains one of the main barriers to their widespread adoption. الاضافه الي ذلك, the metal-ceramic bond requires advanced technology and precision to ensure a durable and high-quality interface.

لكن, with continuous advancements in manufacturing technology, the production costs of AMB ceramic substrates are gradually decreasing. As a result, their potential for application in emerging sectors such as electric vehicles, 5G communication, and high-performance computing looks very promising.

Conclusion

AMB ceramic substrates, as a high-performance composite material, offer outstanding thermal management, electrical insulation, and mechanical strength. They have become a critical component in power electronics, LED lighting, السيارات الكهربائية, and communication devices. As manufacturing technologies improve, AMB ceramic substrates are expected to play an even more significant role in driving innovation across various high-tech industries, paving the way for the continued development of next-generation electronics.

جيم

جيم