EV/5G High-Performance Ceramic Substrates :

A Key Enabler of High-Performance Electronics

The demand for advanced, high-performance electronic systems is escalating as technologies like electric vehicles (EVs) and 5G networks evolve. To meet these demands, the reliability, efficiency, and miniaturization of electronic components must be optimized. One critical material that is playing a pivotal role in enabling these advancements is ceramic substrates. In this blog, we will explore how ceramic substrates are contributing to the development of EVs and 5G technologies, and why they are becoming indispensable in high-performance electronics.

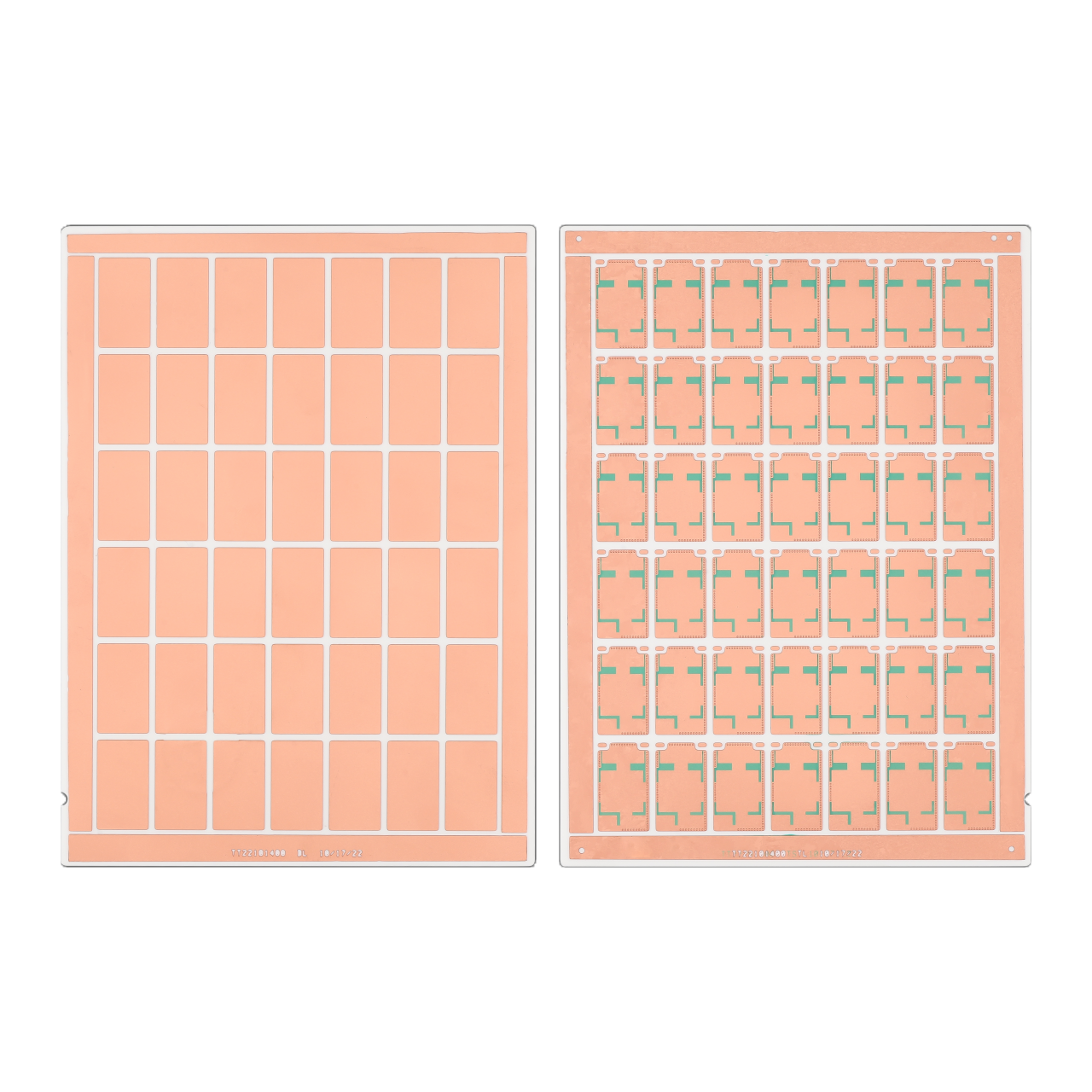

1. Understanding Ceramic Substrates

Ceramic substrates are materials used as the foundation for electronic components. These substrates are typically made from various advanced ceramics, such as alumina (알₂O₃), 질화알루미늄 (알엔(AlN)), silicon nitride (Si₃N₄), and beryllium oxide (BeO). They provide a stable, reliable platform for electronic devices, offering superior thermal conductivity, 전기 절연, 그리고 기계적인 힘.

In particular, ceramic substrates are crucial in applications where thermal management and electrical isolation are essential, which is exactly the case in high-performance electronics like electric vehicles and 5G communication systems.

Key Properties of Ceramic Substrates:

- High Thermal Conductivity: Ceramic materials such as AlN can conduct heat efficiently, making them ideal for systems that generate significant heat, such as power electronics.

- Electrical Insulation: Ceramics are excellent insulators, providing necessary isolation between components in high-voltage or high-frequency systems.

- Mechanical Strength: Ceramic substrates have high tensile and flexural strength, making them durable and reliable even in harsh conditions.

- Chemical Stability: Many ceramics offer resistance to corrosion, oxidation, and other environmental factors, ensuring long-term reliability.

2. Ceramic Substrates in Electric Vehicles (EVs)

Electric vehicles (EVs) are at the forefront of the shift towards sustainable and green transportation. As EVs become more complex, 능률적인, and powerful, the role of advanced materials in the power electronics systems, particularly battery management, power inverters, and motor drives, is growing. Ceramic substrates are crucial in enhancing the performance and longevity of these systems.

Key Applications of Ceramic Substrates in EVs:

Power Electronics:

Power electronics in EVs, such as inverters, converters, and DC-DC converters, are responsible for managing the energy flow between the battery, motor, and other components. These devices generate a lot of heat during operation, and managing this heat is critical to ensure efficiency and reliability.

- 알루미늄 질화물 (알엔(AlN)) and Silicon Nitride (Si₃N₄) ceramics are often used in power modules because of their high thermal conductivity. These ceramics help dissipate heat efficiently, preventing overheating of sensitive components and improving the overall performance of the power system.

- Thermal Management: The high thermal conductivity of ceramic substrates enables better heat dissipation, ensuring that the temperature of power electronics remains within optimal operating ranges.

- Electrical Insulation: Ceramic materials also provide electrical insulation between different power circuit components, helping to prevent short circuits and ensuring the safety of the vehicle.

Battery Management Systems (BMS):

Efficient battery management is key to extending the life of EV batteries and optimizing their performance. Ceramic substrates are used in battery management systems (BMS) to provide reliable and precise monitoring of voltage, temperature, and other parameters.

- Aluminum Oxide (알₂O₃) is commonly used in ceramic substrates for BMS because of its high insulating properties and thermal stability. It ensures that the battery cells remain safe and functional over long periods of charging and discharging cycles.

Electric Motor Drives:

Electric motors in EVs rely on efficient power conversion systems to drive the wheels. These systems require effective heat management to avoid performance degradation.

- Ceramic substrates, especially AlN and Si₃N₄, are used to dissipate the heat generated by electric motor controllers and other components. The materials’ mechanical strength also ensures that the motors remain durable even under stress.

Benefits of Ceramic Substrates for EVs:

- Improved Reliability: Ceramic materials help ensure the longevity and reliability of power electronics systems by preventing thermal and electrical failures.

- Enhanced Performance: By improving heat dissipation, ceramics enable EV systems to perform at higher efficiencies, leading to better range and faster charging times.

- Safety: The high electrical insulation properties of ceramics help protect EVs from electrical faults, enhancing safety for users.

3. Ceramic Substrates in 5G Technologies

As the world transitions into the era of 5G communication, there is an ever-increasing demand for components that can support ultra-high frequencies, faster data speeds, and more efficient power management. Ceramic substrates are increasingly being used in 5G technologies, particularly in the areas of power amplifiers, antenna systems, and microwave devices.

Key Applications of Ceramic Substrates in 5G:

Power Amplifiers (PAs):

In 5G communication systems, power amplifiers are responsible for boosting the signal strength for transmission. These amplifiers operate at high frequencies and generate significant heat during operation.

- 알루미늄 질화물 (알엔(AlN)) is the material of choice for 5G power amplifiers because of its high thermal conductivity. The material effectively dissipates heat, allowing power amplifiers to operate efficiently without the risk of overheating.

Antenna Systems:

The antenna systems used in 5G networks must be able to handle high-frequency signals, and they need to be compact and efficient.

- Ceramic substrates are used in 5G antenna systems because they provide excellent electrical insulation while also offering high dielectric constants that help enhance signal transmission efficiency.

- Ceramic antennas can be designed to operate at higher frequencies without sacrificing performance, making them ideal for 5G networks.

Microwave Devices:

5G systems rely on microwave devices such as filters, oscillators, and multiplexers to manage the high-frequency signals in the network. These devices need to be precise and stable to ensure reliable signal transmission.

- Ceramic substrates are used to build microwave devices because they offer excellent signal integrity and low loss at high frequencies. Materials like Barium Titanate (BaTiO₃) and AlN are commonly used in microwave applications due to their high dielectric properties.

Benefits of Ceramic Substrates for 5G:

- High Frequency Performance: Ceramic substrates are ideal for 5G applications because they can support ultra-high-frequency signals without significant signal loss.

- Miniaturization: Ceramic materials allow for smaller and more compact designs, which are critical for the miniaturization of 5G devices.

- Thermal Management: As 5G devices generate a lot of heat, ceramic substrates ensure efficient thermal management, improving the longevity and reliability of 5G components.

4. Why Ceramic Substrates Are the Future of EV and 5G Electronics

As the global demand for electric vehicles and 5G technologies continues to grow, the need for materials that can efficiently handle the challenges of thermal management, 전기 절연, and mechanical reliability becomes more crucial. Ceramic substrates are uniquely positioned to meet these needs. Their high thermal conductivity, excellent electrical insulation, and mechanical strength make them ideal for both EVs and 5G applications.

By enabling the development of more reliable, 능률적인, and compact electronic systems, ceramic substrates play a pivotal role in the realization of next-generation technologies. With their broad range of applications and exceptional performance characteristics, ceramic substrates are likely to remain a cornerstone material in the future of high-performance electronics.

Conclusion

In conclusion, ceramic substrates are an essential material in the development of electric vehicles and 5G technologies, where they provide critical benefits such as thermal management, 전기 절연, and mechanical reliability. As these industries continue to grow and evolve, ceramic substrates will remain a key enabler of high-performance, sustainable, and efficient electronic systems. Whether in the power electronics of EVs or the high-frequency components of 5G networks, ceramic substrates will continue to drive technological innovation, helping to shape the future of mobility and communication.

김

김