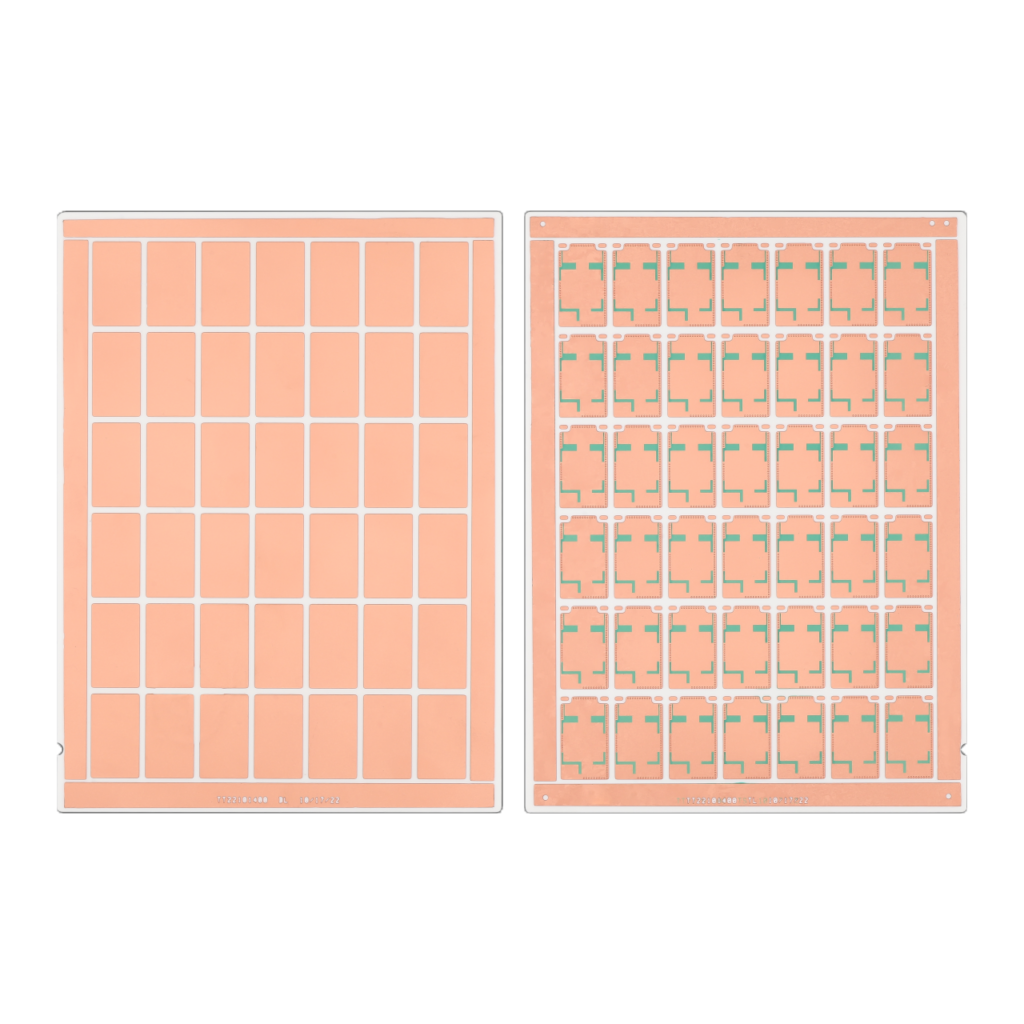

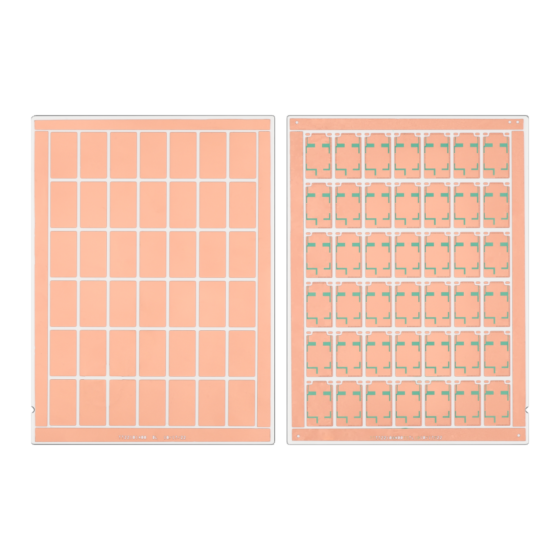

DBC ceramic substrate

Direct Bonding Copper

Material: Alumina ceramic/ZTA

Thickness: 0.32/0.635

Graphic tolerance: ±0.03

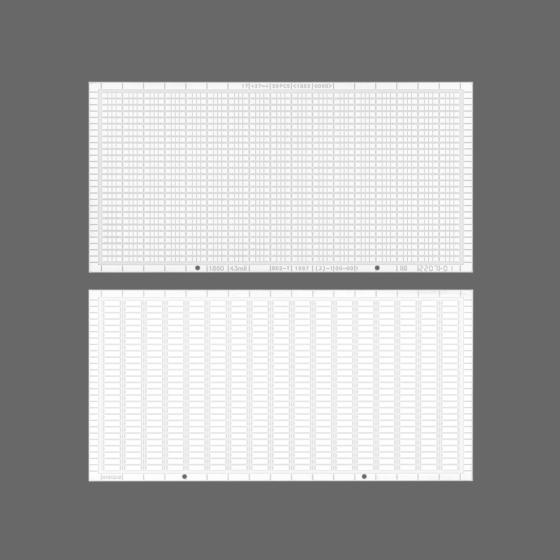

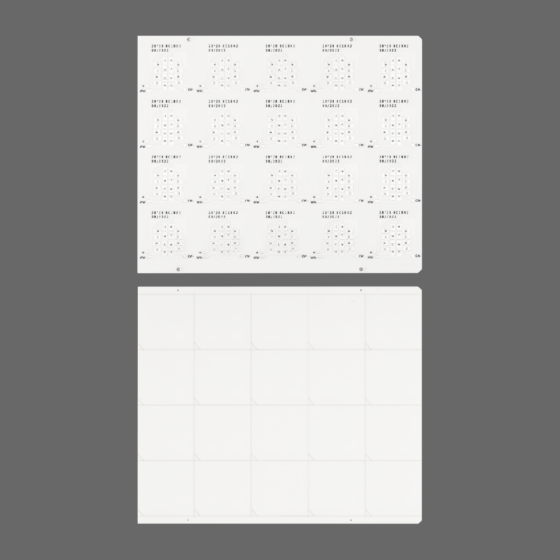

Product size: 109.2*54.5mm

Peel strength:>5N/mm

Insulation strength:>15K

Features: Copper and ceramic are chemically bonded, and have the characteristics of high thermal conductivity, high insulation, high mechanical strength, and low expansion of alumina ceramics. It also has the high conductivity and excellent welding performance of oxygen-free copper, and can etch various graphics like PCB circuit boards; It has excellent conductivity, strong current carrying capacity, and ZTA ceramic substrates have higher bending strength and good toughness. Compared with alumina substrate DBC, it can better withstand cold and hot shocks and has better reliability.

Application areas: Mainly used in semiconductor refrigeration components, used in aerospace, communication equipment refrigeration and heat dissipation, high-speed rail, new energy vehicles, photovoltaic power generation, and industrial control IGBT modules.

GIM

GIM

123